In between projects I like to do some shop organizations.

This is an organization of my taping tools that makes the process of picking and taping much faster.

The decision matrix for which tap to use and what hole size to drill comes with experience.

After deciding large hole vs small hole then it's which type of tap, I use one of three types:

- long lead in

- 2 flute

- bottoming

FYI, there is only one reason I have sooo many taps and holders; Estate Sales

I have a huge reserve of these items that I pay between 1/4 to 1/10 full price.

The set up required a drawer slide shelf

This slides out from the peg board wall across from the drill press

This is crown jewel, I wanted Hi-Low-Med drill sizes and the three aforementioned taps grouped together, it is a real grab and go set up.

The drill range is around 55% - 85%

In addition I have the most common sizes loaded into both short and long bar handles.

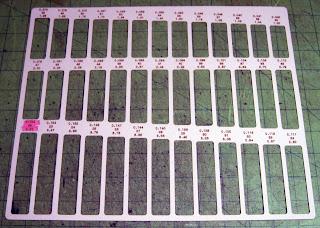

The short tap handles are in this rack

The long are in this rack

I buy any long taps I come across because I would likely never buy one for a one time use.

So the opening for all this is the 3D45 printer, and the Glowforge

I've been experimenting with the use of 1/8" draft board and eco-abs from Dremel.

Basically I would not 3D print a flat sheet so that's where the GF comes in

The 3D45 then is for parts that can be thought of as castings. I print the the tap hole and then tap them afterwards.

The draft board needs to be finished after cutting, I use 2-3 coats Minwax water based Poly.