Have been using the CNC Sherline Mill for about 10 years and finally got tired of adjusting the backlash every hour or two of milling.

I kept a record of the backlash history and had the system down to about an Hour to do all 3 axis.

It was my last two sided milling that tipped me over the edge; you need to know that the Z axis is accurate

Anyhow, since the last time I looked into it Sherline developed their own Kit, so I went for it

Took about 3 weeks to get, seems to be a high demand.

Installation went smoothly, took about 4 hours to get the whole system in place 2 hours to mount the chip guards and another hour to make some changes on Mach 3.

So it is a stressful install; the scariest part is trying to be certain you don't unwind any of the ball bearings. Sherline doesn't give any indication where the max point is on each carriage.

The ways covers were included with my order but I think there needs to be much more attention payed to the installation; they could make some of the attachments built in. However, when installed they work beautifully.

The Z axis sounds SOO much better now, it used to really squeal, now its silent

I had to switch the Units on Mach 3 to get the inches distance corrected. All 3 axis were set to 32000, now I have them set to around 20033...

Indeed the repeatability on all 3 is in the 1/2 thou range just beautiful!

I had to remake the Z axis reinforcement attachment at the top to accommodate the new motor mounts.

I love ALL Crafts and have a fantastic shop where I mostly make tools for shoe Making and Shoes Trained as a Draftsman over 40 years ago I spent most of that time in Advanced Vehicle Engineering. With a BFA in Crafts from CCS I have been making art in my studio all that time too. I currently teach Leather working & Shoe Making at CCS in Detroit

Sunday, September 9, 2018

Sunday, July 29, 2018

Bailey No. 6 Hand Plane - New Handle

Got this No. 6 to round out my collection and like many of these vintage pieces the handle top was broken off and missing

I know that you can find them on the net but I decided to make it myself. Also decided to make from Cherry wood. The knob is original bu may need an upgrade as well some day.

I copied the original shape in CAD but then decided to go one better and make it my own

I developed the whole shape in CAD and tried out the fit with paper cutouts.

Two things had to be confirmed with the paper cutouts; The size of the handle and the location of the 30 deg. hole.

The original I felt was a little too small front to back so I looked at increasing that dimension but then I started thinking about a pistol grip

With full size finger forms there is only room for three fingers but often I found using with my index finger aiming forward is comfortable too

This is a tow sided milling and so you have to be able to index the other side accurately

I left 0.030" from the center of the laminate and so ended up with 0.060" of web between the stock and part

The real problem with this project was getting the hole down the center at 30 deg.

Drilling is impossible

I cut two wood panels and on the radial arm saw cut a groove at 30 deg.

Bonded them together with Gorilla Glue and when the part was finished I could pass a drill thru for clean-up

Sorry no pictures of the blank

I know that you can find them on the net but I decided to make it myself. Also decided to make from Cherry wood. The knob is original bu may need an upgrade as well some day.

I copied the original shape in CAD but then decided to go one better and make it my own

I developed the whole shape in CAD and tried out the fit with paper cutouts.

Two things had to be confirmed with the paper cutouts; The size of the handle and the location of the 30 deg. hole.

The original I felt was a little too small front to back so I looked at increasing that dimension but then I started thinking about a pistol grip

With full size finger forms there is only room for three fingers but often I found using with my index finger aiming forward is comfortable too

This is a tow sided milling and so you have to be able to index the other side accurately

I left 0.030" from the center of the laminate and so ended up with 0.060" of web between the stock and part

Drilling is impossible

I cut two wood panels and on the radial arm saw cut a groove at 30 deg.

Bonded them together with Gorilla Glue and when the part was finished I could pass a drill thru for clean-up

Sorry no pictures of the blank

Saturday, March 24, 2018

DIY Die Filer - Sherline Based

Have been wanting and looking for a Die filer for a long time; the price of even the most clapped-out, used, rusty piece of junk is $500 and up.

My most recent search finally led me to the DIY world.

Some of these are good machines in that they are robust however I wanted and needed a smaller version.

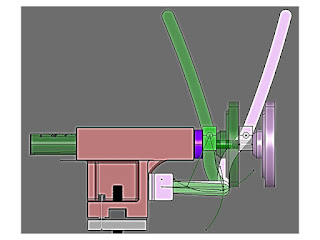

I had an old spare Sherline motor/spindle assem. and realized that this was a good starting point.

One of the things that I do not like about any of the available devices out there is the height; they are all a mile high and require a lot of space for the "once a year usage they get.

I wanted to design and make a very low profile machine.

The key to the low profile is having a sliding file clamp instead of the file clamp and the pin fixed together. This requires the file to be clamped off to the side of the pin.

The offset of the file is on the down-stroke side of the system.

This is the system at full up, I have exactly 1" stroke.

Instead of slots (which I hate making) I went with a 0 - 3 - 6 degrees set of holes.

The thing with the Sherline is the beautiful speed control!

My most recent search finally led me to the DIY world.

Some of these are good machines in that they are robust however I wanted and needed a smaller version.

I had an old spare Sherline motor/spindle assem. and realized that this was a good starting point.

One of the things that I do not like about any of the available devices out there is the height; they are all a mile high and require a lot of space for the "once a year usage they get.

I wanted to design and make a very low profile machine.

The key to the low profile is having a sliding file clamp instead of the file clamp and the pin fixed together. This requires the file to be clamped off to the side of the pin.

This is the system at full up, I have exactly 1" stroke.

Instead of slots (which I hate making) I went with a 0 - 3 - 6 degrees set of holes.

Saturday, March 3, 2018

LittleMachineShop Mini Lathe 5200 - Auto Feed - Adjustable Stop

I looked at what many other great minds did and took my own approach to the auto feed stop mechanism.

I had an old micrometer base from another project and decided that it would give me the easiest adjustability.

The innovation here is the L bracket with a slot

The difficulty is the height that is available; there is not much!

Under the mount shown above is a large thumb screw to tighten the mounting to the L bracket

I haven't had much time with it so we will see

I had an old micrometer base from another project and decided that it would give me the easiest adjustability.

The innovation here is the L bracket with a slot

The difficulty is the height that is available; there is not much!

Under the mount shown above is a large thumb screw to tighten the mounting to the L bracket

I haven't had much time with it so we will see

Friday, March 2, 2018

LittleMachineShop Mini Lathe 5200 - Lever Action Tail Stock

When I got the LMS 5200 I knew I wanted to add the tailstock lever to the tools options

I came up with this design that fits in to my "retrofit" theory

I ordered another complete tailstock and designed a system that I think meets all requirements

The main complication is being able to get the MT2 OUT after you slam it home

The tailstock converts pretty easily

After using it a couple of times I realized that the small thumb wheel was totally inadequate because it has to be turned in the 1.5" to engage the MT and kick it out so I went back to the original hand wheel.

I remade the lever out of 0.25" aluminum and now have a much more robust product.

I get over 1.5" of travel and retain the exact features of the original tailstock

Basic cad design

I came up with this design that fits in to my "retrofit" theory

I ordered another complete tailstock and designed a system that I think meets all requirements

The main complication is being able to get the MT2 OUT after you slam it home

The tailstock converts pretty easily

After using it a couple of times I realized that the small thumb wheel was totally inadequate because it has to be turned in the 1.5" to engage the MT and kick it out so I went back to the original hand wheel.

I remade the lever out of 0.25" aluminum and now have a much more robust product.

Basic cad design

Friday, February 9, 2018

LittleMachineShop.com Hi-torque Mini Lathe 5200

After much research I decided to go with the The LittleMachineShop.com Hi-torque Mini Lathe

I do not recommend the machine.

I really wanted a vintage machine and would have payed as much for a good one but it became clear that the vintage bench top machines have some pretty small Pass-Thru, and Pass-Thru to me is King.

I don't understand the manufacturers reluctance to making large pass thru, its the number one best easiest way to work but is hard to come by. I passed up a beautiful machine on EBay do to shipping and size issues that had a 1.25 pass thru!

The LMS mini has a 20mm thru hole so that 3/4" stock goes thru no problem.

I am also constrained by the basement workshop location. It rolls away into a little slot and has to be pulled out to use.

FYI Shop Organization tip: I'm using a Shoe organizer for scrap metal storage

I made this custom bench for it that includes a drawer and a shelf with a drop down door.

I wanted the lathe at a height that would be comfortable sitting or standing

The optional chip tray is about 14" x 35" so the bench top was an easy 16" x 36"

Drawer

05.12.18

After a few hours on it I would not recommend it, try your luck with another version of the same machine. Its a great size just a little flaky, the speed control is in the wrong place, the tail-stock is not repeatable, and the cross-slide assembly is annoying to name a few.

11.02.18

Another issue is the DRO; not very reliable, and lets face it that's all we ask of them.

06.30.19

So reading and trying many things, buying tooling here and there I came across a quote that I will put into my own words: You can think of a lathe as a "kit" machine Always requiring fix and repair; FIAT... Fix and repair daily!

If take this approach the disappointment of the the "out of box" experience can be mitigated.

After getting used to the 5200 I will say go with one of the other versions out there.

I feel like the cross slide is flimsy and the readouts are barely held on.I do not recommend the machine.

I really wanted a vintage machine and would have payed as much for a good one but it became clear that the vintage bench top machines have some pretty small Pass-Thru, and Pass-Thru to me is King.

I don't understand the manufacturers reluctance to making large pass thru, its the number one best easiest way to work but is hard to come by. I passed up a beautiful machine on EBay do to shipping and size issues that had a 1.25 pass thru!

The LMS mini has a 20mm thru hole so that 3/4" stock goes thru no problem.

I am also constrained by the basement workshop location. It rolls away into a little slot and has to be pulled out to use.

FYI Shop Organization tip: I'm using a Shoe organizer for scrap metal storage

I made this custom bench for it that includes a drawer and a shelf with a drop down door.

I wanted the lathe at a height that would be comfortable sitting or standing

The optional chip tray is about 14" x 35" so the bench top was an easy 16" x 36"

Drawer

05.12.18

After a few hours on it I would not recommend it, try your luck with another version of the same machine. Its a great size just a little flaky, the speed control is in the wrong place, the tail-stock is not repeatable, and the cross-slide assembly is annoying to name a few.

11.02.18

Another issue is the DRO; not very reliable, and lets face it that's all we ask of them.

06.30.19

So reading and trying many things, buying tooling here and there I came across a quote that I will put into my own words: You can think of a lathe as a "kit" machine Always requiring fix and repair; FIAT... Fix and repair daily!

If take this approach the disappointment of the the "out of box" experience can be mitigated.

Sunday, January 21, 2018

Air Nailer - Stapler Orginization / Storage

I use two staplers and one nailer for shoe making and have two other nailers and one other stapler.

A little hard to see but the best answer so far is a set of desk top file holders!

I found this at an estate sale for a couple of bucks.

Hanging them was fine until the collection grew.

A little hard to see but the best answer so far is a set of desk top file holders!

I found this at an estate sale for a couple of bucks.

Hanging them was fine until the collection grew.

Tuesday, January 9, 2018

Sherline Lathe - Lever Action Tail Stock

I really wish I had made this years ago but now I have it.

With the 0.050" per turn on the standard tail stock it takes some time to get a deep hole drilled.

I did some research to see which mechanism might work out and then bought a tail stock blank to build from.

I get over 1.25' travel

I bought a No. 0 taper reamer so I can use all of the set-ups from the standard tail stock

With the 0.050" per turn on the standard tail stock it takes some time to get a deep hole drilled.

I did some research to see which mechanism might work out and then bought a tail stock blank to build from.

I get over 1.25' travel

I bought a No. 0 taper reamer so I can use all of the set-ups from the standard tail stock

Subscribe to:

Posts (Atom)