The Glowforge has (as with all new tools) aloowed for the creation of objects that I would never have tackled before.

So there are two layers of drills with storage beneath in one drawer and fractional in the other.

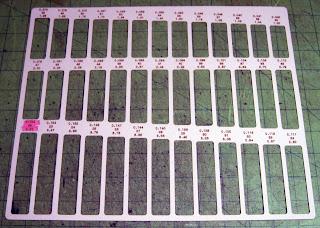

I came across this MonoCraft storage box and repurposed it to the job of storing spare number set drills.

I had previously had them each in a different container; terrible!

I spent the hours to lay out the format and add the text.

Using the Maple 1/8th board from Glowforge for the top and 1/8th Draft board for the bottom of each I nailed them together.

The veneers from GF are pre-finished this is actually super nice. If you were making hundreds of things you would have to try something else.

Having made a couple of things I now understand that the thing you have to figure out before you start cutting is how you are going to attach these vary thin parts.

I've been doing prov-out cuts in paper and this is really important!

I always make a change or find a mistake, in this case I checked that all the bits would fit and found a typo.