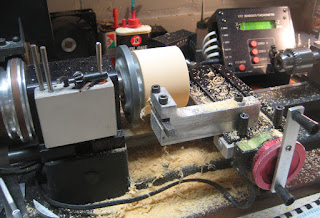

To machine these over size wood discs WITHOUT setting up the riser blocks I went ahead and made a quickie bit holder.

Obviously not stiff enough for metals but for this Bass wood it is very functional.

I used a piece of scrap that had been waiting around for years until the correct part came out of it.

Now I can get well over 3 inch dia without doing anything other than bolt on the new bit holder

Would have been better to reach over to include the far hold down on the cross-slide but the scrap piece ran out.

I love ALL Crafts and have a fantastic shop where I mostly make tools for shoe Making and Shoes Trained as a Draftsman over 40 years ago I spent most of that time in Advanced Vehicle Engineering. With a BFA in Crafts from CCS I have been making art in my studio all that time too. I currently teach Leather working & Shoe Making at CCS in Detroit

Wednesday, October 11, 2017

Sunday, October 8, 2017

DIY Acrylic (see thru) Metric Scale

This Acrylic Metric Scale was made back in 1984 when I was full time (56hrs) at Mercury Metal-craft in Warren Mi.

The Kozlowski's owned and operated this shop and it was fundamental to forming my life and skills sets that I now appreciate and rely on daily.

The shop was divided into two half's; the sheet-metal model making side and the metal removal side.

Hired by my High school friend James Kozlowski I was primarily working in the inspection room. The inspection room was a small but well maintained part of the complete puzzle that made up all of the services offered.

My main mentor in the inspection room was a fellow by the name of Robert Demchak Great guy; funny, talented, (Barber Shop Tenor) he too was instrumental in my understanding of Tolerancing and its effects on costs.

Often on the sheet-metal side we in the inspections room had to verify both the wood pattern and the parts made and checked on it. Often to check the pattern we would have to take measurements from the "brownline" provided by the customer usually Ford, American Motors, and GM. I was told that Chrysler was avoided because "they didn't pay there bills" some things never change.

The see thru scale was something we made for ourselves in the inspection department and I especially like the one that I came up with.

A 3/4" piece of acrylic machined, hand scribed, and professionally lettered, I still use it (maybe once a year) to this day.

The Kozlowski's owned and operated this shop and it was fundamental to forming my life and skills sets that I now appreciate and rely on daily.

The shop was divided into two half's; the sheet-metal model making side and the metal removal side.

Hired by my High school friend James Kozlowski I was primarily working in the inspection room. The inspection room was a small but well maintained part of the complete puzzle that made up all of the services offered.

My main mentor in the inspection room was a fellow by the name of Robert Demchak Great guy; funny, talented, (Barber Shop Tenor) he too was instrumental in my understanding of Tolerancing and its effects on costs.

Often on the sheet-metal side we in the inspections room had to verify both the wood pattern and the parts made and checked on it. Often to check the pattern we would have to take measurements from the "brownline" provided by the customer usually Ford, American Motors, and GM. I was told that Chrysler was avoided because "they didn't pay there bills" some things never change.

The see thru scale was something we made for ourselves in the inspection department and I especially like the one that I came up with.

A 3/4" piece of acrylic machined, hand scribed, and professionally lettered, I still use it (maybe once a year) to this day.

Subscribe to:

Comments (Atom)