My most recent search finally led me to the DIY world.

Some of these are good machines in that they are robust however I wanted and needed a smaller version.

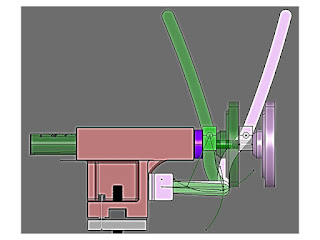

I had an old spare Sherline motor/spindle assem. and realized that this was a good starting point.

One of the things that I do not like about any of the available devices out there is the height; they are all a mile high and require a lot of space for the "once a year usage they get.

I wanted to design and make a very low profile machine.

The key to the low profile is having a sliding file clamp instead of the file clamp and the pin fixed together. This requires the file to be clamped off to the side of the pin.

This is the system at full up, I have exactly 1" stroke.

Instead of slots (which I hate making) I went with a 0 - 3 - 6 degrees set of holes.