Very little to be found on this thing; pretty rare

I'm willing to say that I may have the only working version of this machine

The gears were broken I'm sure because let's face this thing is

fussy, complicated, requires sharpening, and in general would have been

more trouble that its worth for your average shoe maker.

You kind of need to be a tool nerd / engineer to run it.

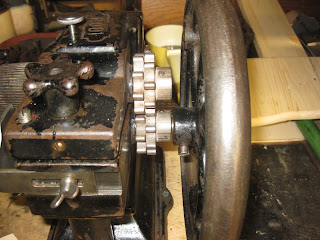

It needed new gears unfortunately but I had the broken pieces so was able to recreate them

I 3d modeled them and 3d printed one set

The next set was 3d metal NOT cheap about $275, but to machine them would have been thousands

Reverse engineered what our Grandfathers did so many years ago.

The new gears come with a thin plating; VERY tricky sizing because the 3d metal is NOT predictable due to shrinkage

To be truthful I have no idea how it was intended to work; this was a very complete machine but cutting the groove as I have it was not possible. I knew what I wanted so I modified it to do it!

I would like to find the patent drawings as they would illuminate some of the details and maybe shed light on how they intended to use it.

Finished and bolted to the table

It takes a channel out for lasting, if you are a hand welter it makes a precise cut.

I've set it up to take about 1.5mm off, that way I have the full lining and outer stack-up flush with the insole upon completion.

If anyone wants to get rid of one I'll take it for the price of shipping.

No comments:

Post a Comment